Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SS-630L

Brand: SKYSIL

Classification: Chemical Auxiliary Agent

Place Of Origin: China

Types Of: Adsorbent, Carbon Black

Application Field: Coating Auxiliary Agents, Leather Auxiliary Agents, Paper Chemicals, Plastic Auxiliary Agents, Rubber Auxiliary Agents, Textile Auxiliary Agents, Water Treatment Chemicals

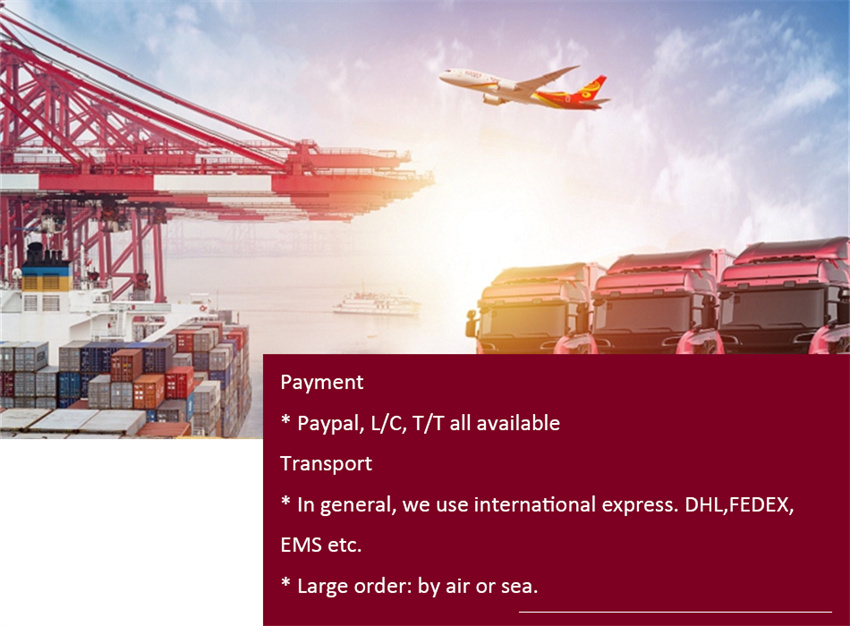

Packaging: 10 kgs/bag, 360 kgs/Pallet, 20 fcl 3.6 Ton With Palletized, 4.5 Ton Without Pallet.

Productivity: 10000 Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800 Ton/Month

Certificate: SGS/ ASTM / ROHS / REACH

HS Code: 2811229000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Feature

In the context of disperse printing processes, silicon dioxide powder may be used as an additive to enhance the performance of the printing ink or dye dispersion. Disperse printing is a technique commonly used for printing on synthetic fibers, such as polyester or nylon, where the colorant is dispersed in a carrier liquid and then applied to the fabric. Here's how silicon dioxide powder can be beneficial in the disperse printing process: Improved Ink Stability: Silicon dioxide powder can help stabilize the ink or dye dispersion by preventing particle settling or agglomeration. It aids in maintaining the homogeneity of the ink or dye suspension, ensuring consistent color distribution and printing quality. Enhanced Color Brilliance: Silicon dioxide particles can act as a pigment dispersant, improving the dispersion of colorants in the printing ink. This results in brighter, more vibrant colors with improved color fastness and wash fastness on the printed fabric. Reduced Foam Formation: Silicon dioxide powder may have defoaming properties, helping to minimize foam formation during the printing process. Foam can negatively impact print quality and cause uneven ink application, so using a defoaming agent can improve printing efficiency and consistency. Increased Ink Viscosity: Silicon dioxide powder can serve as a thickening agent, increasing the viscosity of the printing ink or dye dispersion. Higher viscosity inks are easier to handle and control during the printing process, resulting in better print definition and color registration. Improved Adhesion: Silicon dioxide particles can enhance the adhesion of the ink or dye to the fabric surface, promoting better color penetration and bonding. This helps prevent color bleeding or smudging and ensures sharp, crisp print edges on the fabric. Reduced Drying Time: Silicon dioxide powder may aid in reducing the drying time of the printed fabric by promoting rapid evaporation of the carrier liquid from the ink or dye dispersion. Faster drying times increase production efficiency and throughput in the printing process. When selecting silicon dioxide powder for use in the disperse printing process, it's essential to consider factors such as particle size, surface treatment, and compatibility with the ink or dye system. Conducting compatibility tests and optimizing formulation parameters can help achieve the desired printing results and performance improvements. Additionally, consulting with suppliers or experts in textile printing chemistry can provide valuable guidance in selecting the most suitable silicon dioxide additive for your specific application requirements.

Chemical Data

| Item Type | SS-630L |

| Content of sio2(dry basis) %, | ≥99.0 |

| Porosity ml/g | 1.8-2.0 |

| Oil absorption, g/100g , g/100g | 270-320 |

| Particle Size, um(Malvent,D50) | 5-5.5 |

| Loss on drying(105℃,2Hrs) | ≤5.0 |

| Ignition loss(1000℃,2Hrs) | ≤7.0 |

| Whiteness | ≥90.0 |

| PH(5% Liquor) | 6-7 |

| Surface Treatment | Organic |

Applications

1. High Wood Coatings, Furniture Coating, Floor Coating

2. Printing Inks, Gravure Printing Ink, Offset Printing Ink, Screen Printing Ink, Printing Packing Material.

3. Industrial Coating, Metal baking Coating, Decorative Coating

4. Automotive Coating, Car Coating.

5. Plastic Coating, 3C Coating.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Paint Matting Agent For Inks

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.